Decundi Inspection Services

Comprehensive Pressure Vessel and Utility Inspection Services

We are pleased to have teamed up with Decundi Inspection Services to complement our inspection services and engineering assistance around hazardous location electrical equipment to include the services from Decundi. Decundi Inspection Services LLC in Houston, Texas, provides utility inspection and pressure vessel inspection services for properly evaluating industrial equipment used in oil or gas companies. We have incomparable technical services that help you assess your equipment's compliance to industry standards for function and safety.

Equipment Inspected:

• Pressure Vessels • Structural Steel

• Reactors • Fabrication Equipment

• Heat Exchangers • Fireproofing Equipment

• Fuel Gas Scrubbers • Packaged Equipment

• Instrumental and Electrical

• Chillers Equipment • Boilers

Components Inspected:

• Tray Towers • Compressors • Motors • Cranes • Fin Fan Coolers

• Valves and Actuators • Switch Gear • Coatings • Tanks • Piping

• Mist Eliminators• Refractory • Turbines • Pumps• Analyzers

Inspection Services:

• Welding Inspection • Piping Inspection • Skid Package Inspection

• Vendor Inspection

• Pressure Vessel Inspection • Valve Inspection

• Electrical Inspection • Heat Exchanger Inspection

• Coating Inspection

• Pipeline Maintenance Inspections

Qualilty Control Services:

• Quality Control • Utility Inspection • Pipe Mill Audit • Material Control

Functions Inspected:

After the actual inspection and vendor surveillance is completed, our inspectors will prepare a detailed report which encompasses all the findings during the fabrication and testing stages. All reports are in turn checked by a technical reviewer, who evaluates completeness, before we submit the results to you.

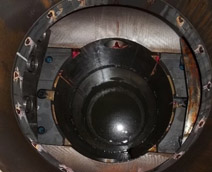

Boiler Inspection

In addition to the above, inspections of Watertube Boilers include witnessing of hydrotesting, installation of stainless steel anchors over which refractory is installed at specified areas inside the firebox and the outside surface of the mud drum and steam drum at the firebox compartment plus parts of the waterwall. After curing of the refractory have been achieved, the surface of the refractory is visually inspected for cracks. As required by the applicable specification for the installation of refractory, all cracks will be subject to repairs as defined by the job scope. In addition, as required by applicable specification for the installation of refractory, at the completion of curing and drying, hammer testing will be carried out using a 1 pound ball-peen hammer at random locations throughout the installed area of the refractory at the mud drum, steam drum and waterwall. Hammer testing of refractory is carried out for verification that no dull sound indicating voids or hollow spots are heard during these tests.

Compressor Inspection

The inspection of compressor components include high-pressure hydrotesting and assembly of cast cylinders and steel cylinders. The compressor should also undergo a spin test to verify that the parameters listed under the equipment's job specifications are met.

B.O.P Control System

Decundi Inspection Services personnel carried out witness testing during factory acceptance testing of Blowout Preventer (B.O.P) Control System with sixteen (16) eleven gallon accumulators (3000 PSI each) with Relief Valve, Fluid Reservoir and Electric Motor with Triplex Pump Assembly. Additional design parameters include but are not limited to the minimum dry metal temperature of -40° F (MDMT), maximum ambient temperature of 40º C, PH, HP, RPM, volts, amps and continuous duty. FAT of this equipment was carried out with satisfactory result. Visual inspection after FAT found the general overall condition of the Blowout Preventer (B.O.P) Control System include but are not limited to the pressure/indicating gauges, regulators, oil level glass on the filter housing associated with the fluid reservoir and, stainless steel tubing were all found to be in good condition at the end of testing. Of specific note, the glass lens on the pressure/indicating gauges on the filter housing were found to be free of cracks, not scuffed up and were found to be transparent (not opaque).

Valve Inspection

Our company employs inspectors knowledgeable about valve inspection. This process includes the setout of valve components prior to assembly, as well as inspection during the hydrostatic tests and function tests of actuated valves.