EX Information Page

Detailed Chapters on Standards and Requirements for International Projects.

Listed below are chapters on various topics in PDF format that are useful resource tools on designing projects to relevant IEC, EN, and other world standards. Detailed information on Russian, Australian and other world requirements are also included along with detailed information on CE Marking and the ATEX Directive in detail.

![]() Understanding Ex Markings. To download the technical paper, please click here

Understanding Ex Markings. To download the technical paper, please click here

To Barrier or not to Barrier, That is the question paper, please click here

To download the Approval Process for Indian Ex Equipment to the PESO Directive, please click here

To download the Source IEx white paper on a Review of Material Suitability of Ex equipment in Corrosive Environments, please click here

To download the Source IEx white paper on Guidance of Application of Ex Equipment based upon Previous Ex standards, please click here

To download the Source IEx white paper on Ex 'X' and 'U' assembly and component certification, please click here

To download the ATEX, IECEx and other Regional Systems presentation from Ron Sinclair, please click here

To download the latest USCG ruling on the use of Ex equipment in the GOM, please click here

To download the full text of ATEX 2014/34/EU as published by Europa, please click here

To download the IP degrees Technical Paper, please click here

To download the Technical Regulations of Customs Union Document (new Russian Ex Scheme) please click here

Chapter 1 - History

In this chapter, we focus on the history of the development of Ex standards as well as the history of the organizations responsible for writing and maintaining the International Standards in place today. Some of the first areas to be classified were coal mines with the presence of coal dust and methane gas. Some of the earliest form of protection concepts including Ex d (flameproof) and Ex i (Intrinsic Safety) were developed for the safe operation of electrical equipment in hazardous locations.

To open up Chapter 1, please click here ![]()

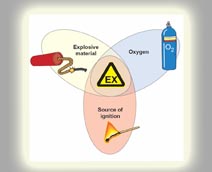

Chapter 2 - Ex Fundamentals

In order to have an explosion, three legs of the triangle need to be present: Fuel, Oxygen and a source of Ignition. This chapter discusses the details of the various explosive hazards that need to be addressed when selecting protection concepts. We also go into detail as to area classification per 60079-10. Some of the obvious sources of ignition are arcing/sparking devices and heat buildup with regards to Ex equipment. Some not so well known hazards include impact, friction and other potential hazards that we go into detail on.

To open up Chapter 2, please click here ![]()

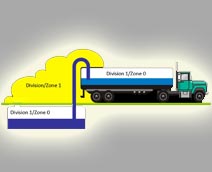

Chapter 3 - Zone Concept

In this chapter, we discuss the Zone concept of area classification in detail for both dust and gas hazards per the relevant IEC & EN Standards. Some of the common questions are how are areas classified, what is the process, who is responsible for this function and what are the practical aspects of placing Ex equipment in particular Zones

To open up Chapter 3, please click here ![]()

Chapter 4 - CE Marking

In this section, we review what exactly the CE Marking is and just as important, what it doesn't mean with regards to electrical equipment and components.

To open up Chapter 4, please click here ![]()

Chapter 5 - ATEX Directive

In this chapter, we review the important parts of the ATEX Directives both for worker safety and products for use in a potentiall explosive environment. We discuss the EC Declaration of Conformity and what to look for and what electrical and non-electrical items are within and outside of the scope of the ATEX Directive.

To open up Chapter 5, please click here ![]()

Chapter 6 - IECEx including adaptation in the US of the IEC

In this section, we review the thought process behind IECEx and how it compares to the ATEX Directive and product certifications and also give a review of the harmonization between EN and IEC standards as well as an overview of the latest acceptance notes by US agencies.

To open up Chapter 6, please click here ![]()

Chapter 7 - Ingress Protection Codes

In this chapter, we review the key parts of IEC & EN 60529 which defines Ingress Protection Codes and how the products are built to meet these requirements along with what are typical industrial IP code application types. Special notice is referenced to supplimental letters following the standard codes.

To open up Chapter 7, please click here ![]()

Chapter 8 - Product Approvals

In this section, we compare the product approval process looking at IEC, IECEx, compliance to the ATEX Directive and how these compare with North American product approval concepts..

To open up Chapter 8, please click here ![]()

Chapter 9 - Low Voltage Directive

In this section, we review the details on compliance to the Low Voltage Directive, what products does this apply to and how manufacturers typically will achieve compliance.

To open up Chapter 9, please click here ![]()

Chapter 10 - IEC Forms of Segregation with Motor Control Centers

In this chapter, we discuss in details the differences of the form of segregation of equipment within IEC Motor Control Centers. When designing MCC's, a significant difference in the level of safety can be achieved by following a higher level of Forms. However, it certainly comes at a cost, so good information to understand when both designing as especially in evaluating competitive product offerings from multiple manufacturers to help compare in effect, apples to apples.

To open up Chapter 10, please click here ![]()

Chapter 11 - EMC Directive

In this section we briefly discuss the EMC Directive and what products does this apply to and what is the process for a manufacture to comply with this directive.

To open up Chapter 11, please click here ![]()

Chapter 12 - EX Protection Concepts

In this section, we review in detail the various EX protection concepts including flameproof, increased safety, intrinsic safety, non-arcing, purging/pressurizing and much more. We go into the details on the differences of construction and what are some of the key points that manufacturers must follow in order to get their equipment certified as well as safely using these protection concepts within a facility.

To open up Chapter 12, please click here ![]()

Chapter 13 - EX Wiring Methods

In this chapter, we discuss the most common wiring methods used in Ex locations around the world including reviewing key cable standards, the use of conduit vs. cabling, where a barrier gland needs to be used and where it doesn't, and some of the key points to remember from the EN & IEC 60079 sets of standards.

To open up Chapter 13, please click here ![]()

Chapter 14 - Cable Support Systems

In this section, we review some of the most common cable support system requirements in the International world and discuss further some of the requirements of IEC 61437 on ladder and tray systems. We also show some typically examples of how cable trays and ladders are typically used in both safe and Ex installations to provide some ideas on how you can incorporated trays, ladders and other support materials into your application.

To open up Chapter 14, please click here ![]()

Chapter 15 - Ex Lighting Fundamentals

In this section, we discuss some of the details on lighting sources available within the Ex industry including LED's, Induction Lighting technology, fluorscent technology and the use of the various HID lighting sources including Metal Halide, High Pressure Sodium and Mercury Vapor lamp types.

To open up Chapter 15, please click here ![]()

Chapter 16 - Area Classification

In this chapter, we show some examples of how various installations are typically classified per IEC 60079-10 and also per the Energy Institute IP15 and compare vs. some North American equivalent type installations.

To open up Chapter 16, please click here ![]()

Chapter 17 - Deluge Standards for Equipment

In this section, we briefly discuss the Deluge Standard and how it applies to Ex equipment located outdoors when potentially subjected to deluge conditions.

To open up Chapter 17, please click here ![]()

Chapter 18 - Testing of Ex Equipment

In this section, we review some of the common testing proceedures used with regards to Ex equipment from both a Testing laboratory as well as internal testing performed by the manufactures above and beyond what is required.

To open up Chapter 18, please click here ![]()

Chapter 19 - Ex Installation Examples

In this section, we show real world installations following IEC requirements and reference some of the world's specific wiring regulations that are not IEC specific but are to country specific requirements.

To open up Chapter 19, please click here ![]()

Chapter 20 - Earthing/Grounding Requirements

In this chapter, we review some of the most common earthing and grounding requirements for installations following International and BS standards as well as reference what is commonly done by large companies.

To open up Chapter 20, please click here ![]()

Chapter 21 - Maintenance Requirements of Ex Equipment

In this section, we discuss what are some of the key details within 60079-17 with regards to maintenance of Ex equipment.

To open up Chapter 21, please click here ![]()

Please Note: The information above is not to be used as the definitive answer for your exact applications and is pulled from many sources around the world. Good engineering judgement is always required and their will be deviations to much of the information above specifically based upon country specific wiring regulations. We strongly recommend reviewing this information in addition to the relevant International Standards, country specific standards and wiring regulations within that country before undertaking design of your installation or product(s). This information is to provide guidance only.